Ut solutio principalis in agro tutelae contra altas temperaturas, technologia pulverisationis panni vitrei et fibrae refractariae promovet emendationem comprehensivam salutis instrumentorum industrialium et efficientiae energiae. Hic articulus proprietates functionis harum duarum technologiarum, casus applicationis et valorem innovationis synergicae examinabit, ut utentibus industriae commendationem technicam praebeat.

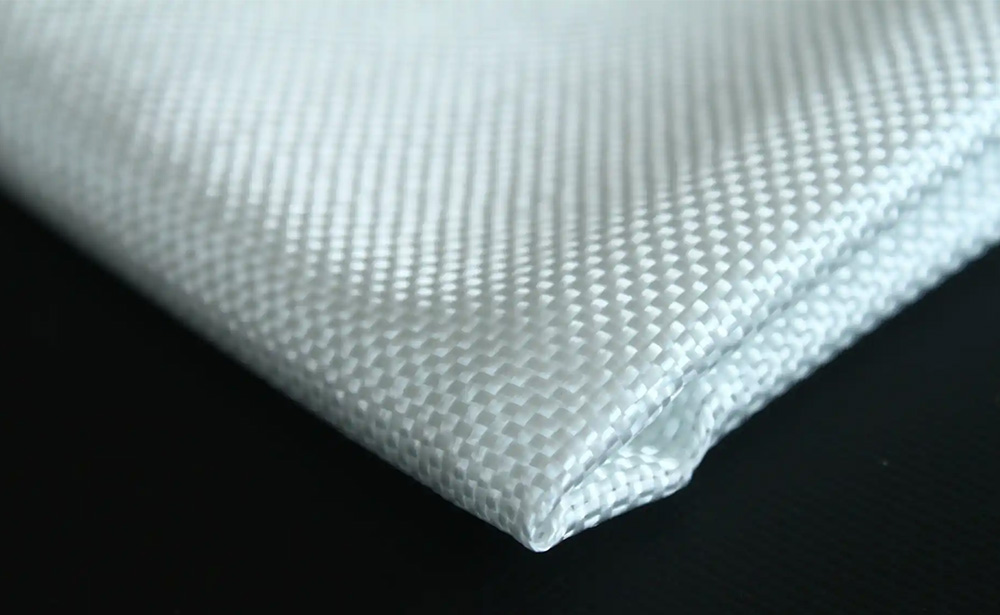

Pannus vitreus: materia fundamentalis ad protectionem contra altas temperaturas

Pannus vitreus e materiis inorganicis non metallicis conditus, per processum specialem ad praeclaram efficaciam praebendam, temperatura alta, corrosione et ambitus complexos in materiam protectivam idealem fit:

1. Resistentia Altae Temperaturae

Consuetudinariumpannus fibrae vitreaeTemperaturas altas supra 500°C sustinere potest, et producta silicae altae condiciones extremas supra 1000°C tolerare possunt. Late in tegumentis fornacum metallurgicarum, insulatione navium spatialium, aliisque condicionibus adhibetur.

2. Proprietates Ignifugae et Insulationis

Eius resistentia flammae propagationem flammarum efficaciter segregare potest, et etiam magnam resistentiam insulationis (10¹²-10¹⁵Ω-cm) habet, quae apta est ad protectionem apparatuum electricorum et insulationem partium electronicarum.

3. Resistentia corrosionis et levitas

Resistentia erosioni acidae et alcalinae eam primam electionem ad protectionem fistularum chemicarum et cisternarum facit; densitate tantum quartae partis chalybis, ad designum leve in industriis aëronauticis et autocineticis confert.

Applicationes typicae:

- Apparatus industrialis ad altam temperaturam: tegumentum fornacis, insulatio tuborum ad altam temperaturam.

- Novus campus energiae: subsidium plani posterioris solaris, amplificatio alae vis venti.

- Technologia electronica: partes undis perspicuae stationis basis 5G, praesidium insulationis motoris summae qualitatis.

Technologia Fibrae Refractariae Pulverisandae: Emendatio Revolutionaria Tegumenti Fornacis Industrialis

Technologia fibrae refractariae per mechanizationem constructionis aspergendae, fibra et ligans mixti directe ad superficiem instrumentorum asperguntur, structura reticulata tridimensionali formata, efficaciam tutelae insigniter augent:

1. Commoda

- Energiae conservatio et consumptio reductio: excellentis obsignationis effectus, caloris iacturam corporis fornacis 30%-50% minuunt, vitam involucri fornacis plus quam bis extendunt.

- Constructio flexibilis: superficiebus curvis complexis et structuris formatis accommodata, crassitudo accurate aptari potest (10-200mm), problema suturarum fragilium productorum fibrae traditionalis solvens.

- Reparatio celeris: reparationem instrumentorum veterum per interrete adiuvat, tempus inoperabile minuit et sumptus sustentationis deminuit.

2. Innovatio materiarum

Substratum fibrae vitreae cum carburo tungsteno, alumina, aliisque technologis obductionis coniungens, resistentiam attritionis et resistentiam altae temperaturae (plus quam 1200°C sustinere) ulterius augere potest, ut necessitatibus arduis fusionis chalybis, reactorum petrochemicorum, et cetera occurrat.

Scenario Applicationis:

- Tegumentum fornacis industrialis: insulatio caloris et protectio refractaria pro fornace explosiva et fornace curationis caloris.

- Instrumenta energiae: tegumentum contra ictum thermalem pro cameris combustionis turbinarum gasi et tubis caldariorum.

- Ars tutelae ambitalis: tegumentum corrosioni resistens pro apparatu curationis gasorum residuorum.

Exempla applicationum synergicarum: integratio technologiae ad novum valorem creandum

1. Systema Protectionis Compositum

In receptaculis petrochemicis,pannus fibrae vitreaeut stratum fundamentale insulationis caloris ponitur, deinde fibrae refractariae ad obsignationem augendam asperguntur, et efficacia comprehensiva energiae conservandae 40% augetur.

2. Innovatio Aerospatialis

Societas aëronautica technologiam pulverisationis ad superficiem materiae basis panni fibrae vitreae modificandam adhibet, quae limitem temperaturae strati insulationis caloris compartimenti machinae ad 1300°C auget et pondus 15% minuit.

Dynamica industriae et inclinationes futurae

1. Augmentatio Capacitatis et Technologiae

Sichuan Fiberglass Group et aliae societates ad accelerandam expansionem capacitatis productionis, capacitatem filorum electronicorum fibrae vitreae 30,000 tonnarum anno 2025, et investigationem et progressionem dielectrici humilis, modificationis producti altae temperaturae, ad accommodandum postulationi technologiae spargendi.

2. Proclivitates Fabricationis Viridis

Technologia fibrarum refractariarum aspergendarum materiae iacturam 50% et emissiones carbonis 20% minuit, quod cum meta globali neutralitatis carbonis congruit.

3. Progressus Intelligentis

Cum algorithmis intellegentiae artificialis ad parametros spargendi optimizandos coniunctum, uniformitatem et crassitudinem tunicae intelligentem moderari potest, et tutelam industrialem ad praecisionem promovet.

Conclusio

Applicatio synergisticapannus fibrae vitreaeEt technologia fibrarum refractariarum aspergendarum fines tutelae industrialis contra altas temperaturas reformat. A fabricatione tradita ad technologiam recentissimam, ambae solutiones efficaces et sustinabiles pro energia, metallurgia, industria aerospatiali, aliisque sectoribus per complementarem efficaciam et innovationem processuum praebent.

Tempus publicationis: XVII Kalendas Apriles, anno MMXXXV